ST 2512 Tracked Screening Machine

ST 2512 is a mobile screening plant that can meet screening needs of different sectors and offer the advantages of being a double-layered screen that Works forced vibration at highest level.

It is a mobile screening machine that can move, can be easily set up, can be used with a single person and shows optimum performance.

Due to its fast set-up time, transportation and easy use, the ST 2512 is ideal for your projects in small or large workspaces in different locations.

Material input into the bunker can be done easily with an excavator, wheel loader or conveyor belt.

A separate calibration can be achieved by preventing the entrance of coarse materials that are subjected to pre-separation into the screen with the slope adjustable bunker grid; as well as preventing bulky materials from damaging the plant.

ST 2512 classifies the materials into three different sizes with double deck screen system and easily changeable screen wire.

ST 2512, has a diesel engine and track system. Machine is powered by high performance hydraulic drive and alternator.

It is a user-friendly machine, as controlled with a remote control by only a person and its speed adjustable features. Hydraulic foldable conveyor belts, on the other hand, enable the facility to be set up in a short time such as 15 minutes and to be gathered at the end of the work, allowing easy and rapid location change and being ready for any task at different places and times.

Thanks to the drum motor that used in the plant system provide a low maintenance cost and high performance. In addition, the central lubrication system ensures that all moving parts are lubricated regularly and automatically, thereby extending the machine’s lifespan and reducing maintenance intervals.

As having the users as the focus, and allowing durable and flexible use, the ST 2512 is also suitable for our high efficiency, low maintenance cost and optimum benefit principles.

With all these features, the ST 2512 is your unique, easy-to-use, low-cost assistant in your business.

Technical Properties

| Capasity | Max. 80 m3/ h |

| Feeding Hopper | 3 m3 |

| Remote Conrolled Hydraulic Tilting Hopper Grid | |

| Main Belt Conveyor Width | 800 mm |

| Speed Adjustable Main Belt Conveyor | |

| Forced Vibratory Special Screening Machine: Eccentric Pivot, 4 Housing | |

| Screen Dimension | 2,5 x 1,25 m |

| Hydraulic Collapsible Belt Conveyor | 3 Pieces |

| Conveyor Belt Drive | Drum Motor |

| Control Panel | Wireless Remote Control |

| Movement Mechanism | Tracked |

| Tier Final IV/ Euro Stage V Diesel Engine | Hatz – 41KW, 1800 RPM |

| Diesel Driven Generator Set | 50-55 kVA |

| Capasity of Oil Tank | 100 lt / 40 lt |

| Capasity of Fuel Tank | 90 lt |

| Transportation Length | 7650 mm |

| Transportation Width | 2520 mm |

| Transportation Height | 3750 mm |

| Transportation Weight | 13200 kg |

Optional Properties

| Piano Mesh Wire and Stretcher |

Why Forced Vibrating Screen?

• Eccentric Pivot

• 4 housings system

• The balance of the sieve with the weight attached to the pivot is taken.

• Even if there is a lot of material on it, there is no need for weight reinforcement.

• The sine curve does not change according to the amount of material. Therefore, even if there is a lot of material, fainting and clogging will not occur.

Other Screen Systems

• Tilting adjustment is not possible.

• 2 housings system

Why Drum Motor?

• Fully enclosed compact structure

• Space saving desing

• High Safety

• Low maintenance cost

• Efficiency

• Energy saving

• Thermal protection

• Low noise level

What Can Be Sieved?

ST 2512 is for ballast, coal, aggregate, turf, soil, sand, construction waste, recycling, salt, agricultural products and any material you want to sieve.

Why Piano Mesh Wire?

• No clogging with moist material.

• Short operation time.

• High rate of flat material passing through.

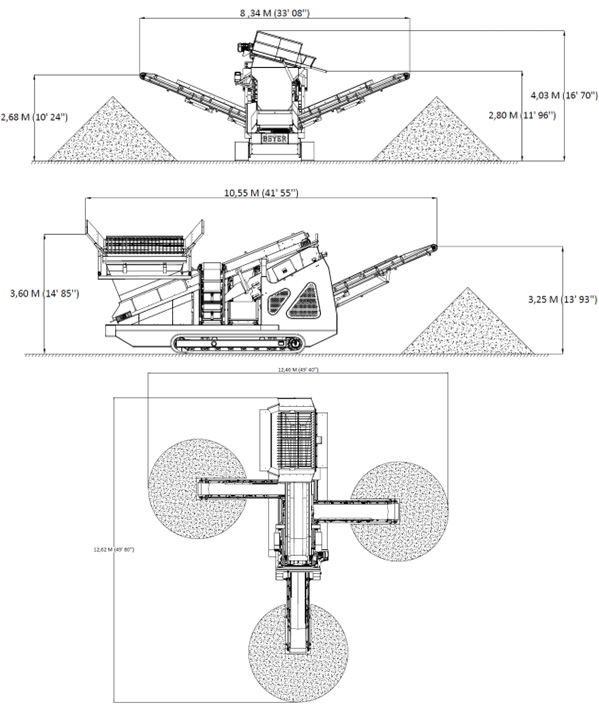

Operational Dimensions

The ST 2512 gives you optimum use of space in small workplaces on the operation sites. Thanks to three different conveyor belts, it uses the space as efficiently as possible by throwing out the material in different directions. Hydraulic folding bands increase the drop height and expand the pile volume. Control panel functions, such as opening conveyor belts, can also be performed with an optional remote control; thus, it contributes to the increase of occupational safety in the workplace. The ST 2512 provides a satisfactory use with its operational dimensions.

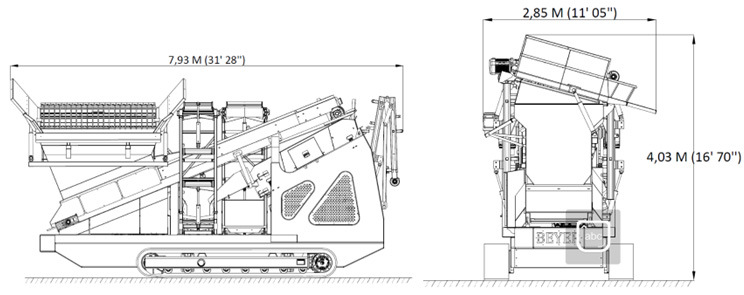

Transportational Dimensions

Thanks to hydraulically closed conveyor belts the tracked screening machine is going to be compact, easily moved up on the “lowbed” and transportation will be occur. The ST 2512, usually loaded to lowbed trailer with highway and Ro-Ro ships with the seaway, this way it can be easily transport. In this way, you can dispatch and it can be ready in a short time to your projects that different locations and thanks to its mobile structure you can use different working areas easily. This transportational feature makes you a saves money both time and costs, will increased operational productivity compared to fixed plants.